Problem: condensation in the duct.

-

What if condensation builds up on the ducts?

A common problem customers have is that when they start living in a class A or higher house with a ventilation system, they notice that the tin ducts that bring in cold outside air are damp and rusty.

There are several reasons for the formation of condensation:

- The air in the duct is colder than the duct surface temperature. The air touching the duct and the metal surface of the duct due to the large temperature difference causes condensation.

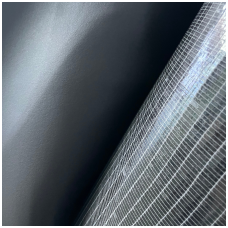

- Leaky or too thinly insulated duct. Even though the duct is insulated, condensation still occurs, probably because the insulation is not properly laid or the thickness is too small. Often the use of stone wool insulation fails to seal everything properly.

- The ducts are blown polyethylene, but the joints are plastic and uninsulated, e.g. Aerfoam sleeve for blown polyethylene duct joints or EPS duct joints.

Effects of wet ducts.

What are the possible consequences?

- Condensation can build up not only on the outside but also on the inside, causing mould, which is dangerous to our health.

- Condensation droplets can fall on ceilings and walls, causing damage to the finish.

- If moisture and condensation accumulate throughout the duct, then it should be checked that the duct is installed correctly (there should be a slope to the outside) and that the right duct or insulation is used.

How can I avoid condensation problems?

- Effectively insulate air extraction sheet ducts using a quality anti-condensation insulation such as https://www.proventas.lt/en/insulation-rotoli-k-flex-st-ad

- If the duct is insulated, check for quality, for gaps, and for appropriate measures. Installation foam and mineral wool are not suitable for this purpose. L'Isolante K-Flex, Armacell manufacturers' insulations: https://www.proventas.lt/en/ventilation-systems/blown-polyethylene-ducts-and-insolation/insulation

- The ducts are special ducts made of EPE, EPS and EPP materials, but the joints (sleeves, joints) are plastic and should be additionally insulated with the above mentioned insulation products: ST tape or Armacell ACE tape. An excellent alternative could be Zehnder's ComfoPipe materials where there are no plastic joints: https://www.proventas.lt/en/search?q=comfopipe

Summary

Duct insulation is an important phase of a ventilation system that requires special attention. Careful selection of insulation materials and quality work can help to avoid condensation problems and maintain the efficiency and durability of the building.